Application of vacuum coating equipment in forming molds and injection molds

The application of vacuum coating equipment in forming molds and injection molds, physical vapor deposition (PVD), ion-enhanced chemical vapor deposition (PACVD), chemical vapor deposition (CVD) and composite processing (nitriding +PVD) have been widely and successfully Used in metal molding and plastic injection molding applications.

Baorui Titanium PVD and PACVD and CVD coatings improve the performance and productivity of punches, dies, hobs and other tools used for forming metals, plastics and other composite materials. Baorui Titanium cooperates extensively with the industrial field to provide solutions for each application.

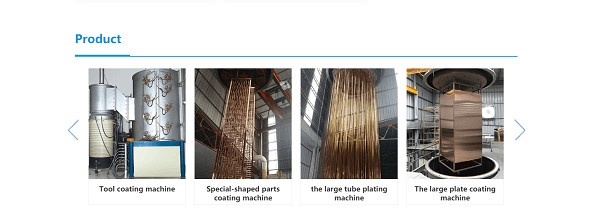

vacuum coating machine,pvd coating machine,pvd vacuum machine,vacuum ion coating machine,multi-arc ion coating machine

►High hardness

►Abrasion resistance

►Resilience

►Low friction coefficient

►Anti-abrasion

►Corrosion resistance

Baorui Titanium has a wide range of coating combinations and rich application experience, and can select suitable coatings for mechanical applications according to the characteristics and functions of the coating to achieve the ideal performance of the tool.

vacuum coating machine,pvd coating machine,pvd vacuum machine,vacuum ion coating machine,multi-arc ion coating machine

►Longer tool life

►Improve the quality of parts

►Reduce the use of lubricants

►Reduce downtime

►Reduce tool maintenance

►Eliminate secondary operations

Baorui Titanium PVD and PACVD and CVD coatings have an extremely good record in improving the performance of tools used in different applications. ►High-strength material forming ►non-ferrous metal material forming ►cold forging ►powder compaction ►dropping and trimming dies ►punching ►hot punching ►die casting, metal injection forming ►hot extrusion and forging ►plastic injection, film extrusion

Baorui Titanium engineers conduct separate evaluations for each different situation. Provide a systematic solution for the stated goal. The choice of coating is based on several key factors and tool performance objectives: ►Tool function ►Tool material ►Tool life expectancy ►Heat treatment ►Workpiece material or resin ►Working temperature ►Tool failure mode